浏览量:

1004

裕东给袋机产品推荐

发布时间:2020/12/25 20:15:30

修改时间:2022/8/23 16:20:01

发布者:温州裕东

联系电话:15858518818

关键词:

描述:

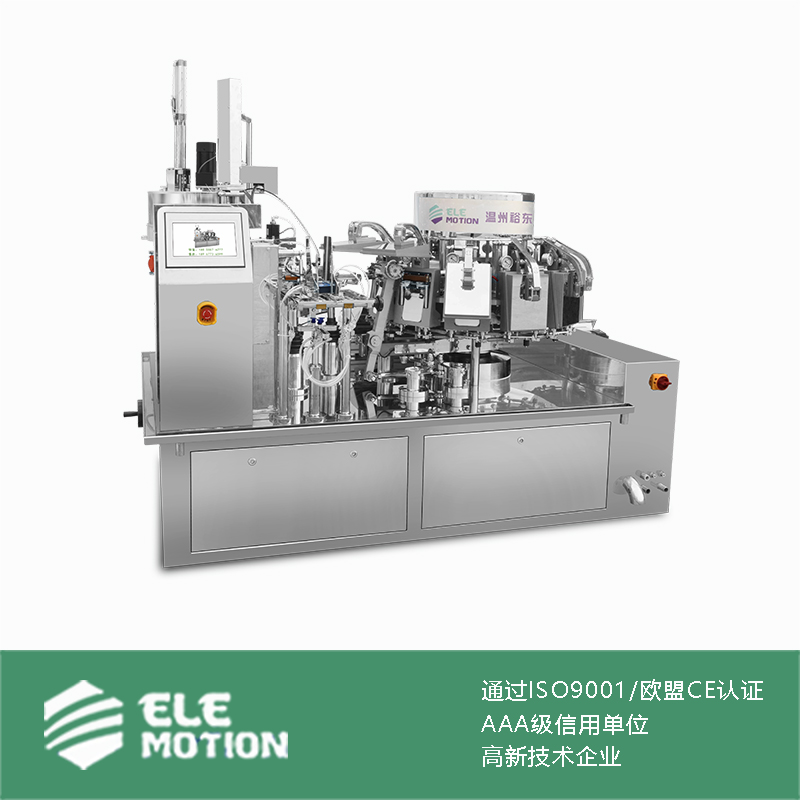

技术参数:YD1216-1018 给袋式包装机

| 机器型号 Machine Model | YD1216-1018 | ||

| 工作流程 Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥下料 ⑦下料 ⑧拉直 ⑨转至真空腔 ⑩盒盖 ⑪抽真空 ⑫封口 ⑬封口冷却 ⑭放气 ⑮出袋 ①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥material feeding ⑦material feeding ⑧bag pulling ⑨passing to vacuum chambers ⑩close the lid ⑪vacuumize ⑫seal ⑬seal&cool ⑭deflate ⑮bag out | ||

| 设备材料 Equipment Material | 304不锈钢 304 stainless steel | ||

| 真空泵 Vacuum Pump | 德国普旭100/上海众德100(选配) BUSCH(German)/ ZD(Shanghai)(optional) | ||

| 气动元件 Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件) SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | ||

| 驱动方式 Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式) Mechanical drive(cam gear lever full mechanical mode) | ||

| 封口方式 Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观 Instant heat sealing and instant cooling, ensure nice sealing appearance | ||

| 包装速度 Packing Speed | 110 - 120包/分钟(根据产品特性和袋型而定) 110 - 120 bag/min(depending on ingredients) | ||

| 包装袋材料 Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋 3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | ||

| 包装袋规格 Pouch Dimension | 宽:50 - 100mm 长:60 - 180mm W:50 - 100mm L:60 - 180mm | ||

| 主机功率Host Power | ≈11KW | ≈11KW | |

| 耗气量Air Consumption | ≥0.8m³/分钟 | ≥0.8m³/min | |

| 驱动电源 Drive Power | 三相五线 380V 50HZ 3-phase 5-wire system 380V 50HZ | ||

| 外形尺寸 Dimension | 2850 x 1600 x 1600mm(L x W x H)(不含提升机) 2850 x 1600 x 1600mm(L x W x H)(without elevator) | ||

| 主机重量Weight | 2.8T | 2.8 Tons | |

| 冷却用水Cooling water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min | |

| 使用环境 Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境 Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | ||

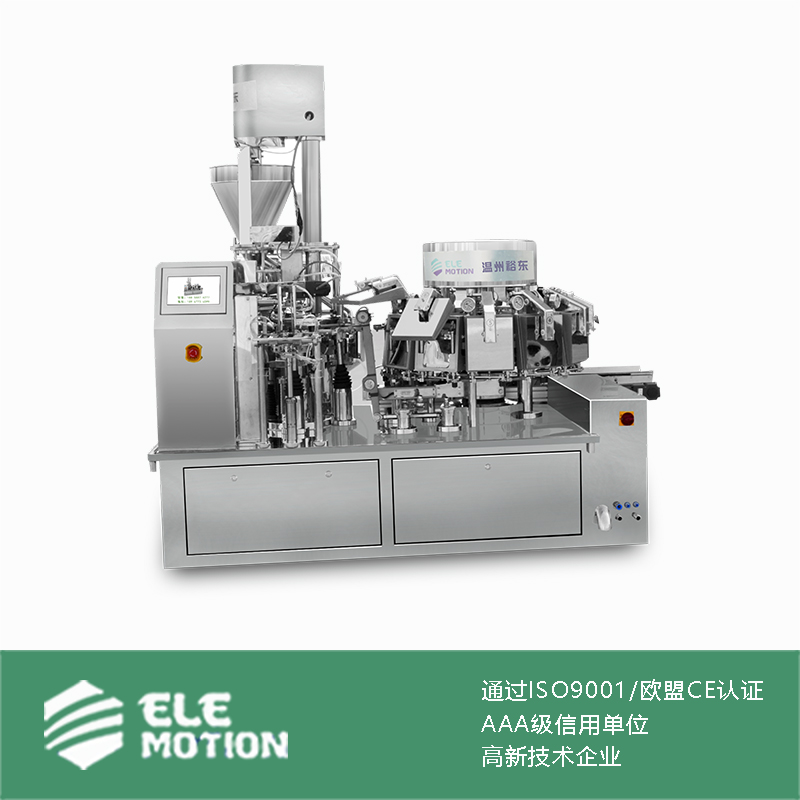

2、YD1014-1018 给袋机

技术参数:YD1014-1018 给袋式包装机

| 机器型号Machine Model | YD1014-1018 | |

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥下料 ⑦拉直 ⑧转至真空腔 ⑨盒盖 ⑩抽真空 ⑪封口 ⑫封口冷却 ⑬放气 ⑭出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥material feeding ⑦bag pulling ⑧passing to vacuum chambers ⑨close the lid ⑩vacuumize ⑪seal ⑫seal&cool ⑬deflate ⑭bag out | |

| 设备材料Equipment Material | 304不锈钢304 stainless steel | |

| 真空泵Vacuum Pump | 德国普旭100/上海众德100(选配)BUSCH(German)/ ZD(Shanghai)(optional) | |

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | |

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | |

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | |

| 包装速度Packing Speed | 100 - 110包/分钟(根据产品特性和袋型而定)100 - 110 bag/min(depending on ingredients) | |

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | |

| 包装袋规格Pouch Dimension | 宽:50 - 100mm 长:60 - 180mmW:50 - 100mm L:60 - 180mm | |

| 主机功率Host Power | ≈9KW | ≈9KW |

| 耗气量Air Consumption | ≥0.8m³/分钟 | ≥0.8m³/min |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | |

| 外形尺寸Dimension | 2700 x 1600 x 1600mm(L x W x H)(不含提升机)2700 x 1600 x 1600mm(L x W x H)(without elevator) | |

| 主机重量Weight | 2.7T | 2.7 Tons |

| 冷却用水Cooling Water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | |

| 机器型号Machine Model | YD1012-1318 | ||

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥下料 ⑦拉直 ⑧转至真空腔 ⑨盒盖 ⑩抽真空 ⑪封口 ⑫封口冷却 ⑬放气 ⑭出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥material feeding ⑦bag pulling ⑧passing to vacuum chambers ⑨close the lid ⑩vacuumize ⑪seal ⑫seal&cool ⑬deflate ⑭bag out | ||

| 设备材料Equipment Material | 304不锈钢304 stainless steel | ||

| 真空泵Vacuum Pump | 德国普旭100/上海众德100(选配)BUSCH(German)/ ZD(Shanghai)(optional) | ||

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | ||

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | ||

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | ||

| 包装速度Packing Speed | 70 - 90包/分钟(根据产品特性和袋型而定)70 - 90 bag/min(depending on ingredients) | ||

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | ||

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 180mmW:55 - 130mm L:60 - 180mm | ||

| 主机功率Host Power | ≈9KW | ≈9KW | |

| 耗气量Air Consumption | ≥0.8m³/分钟 | ≥0.8m³/min | |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | ||

| 外形尺寸Dimension | 2550 x 1600 x 1600mm(L x W x H)(不含提升机)2550 x 1600 x 1600mm(L x W x H)(without elevator) | ||

| 主机重量Weight | 2.5T | 2.5 Tons | |

| 冷却用水Cooling Water | 15-20℃, 3.5升/分钟 | 15-20℃, 3 liters/min | |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | ||

| 机器型号Machine Model | YD810-1318 | |

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥拉直 ⑦转至真空腔 ⑧盒盖 ⑨抽真空 ⑩封口 ⑪封口冷却 ⑫放气 ⑬出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥bag pulling ⑦passing to vacuum chambers ⑧close the lid ⑨vacuumize ⑩seal ⑪seal&cool ⑫deflate ⑬bag out | |

| 设备材料Equipment Material | 304不锈钢304 stainless steel | |

| 真空泵Vacuum Pump | 德国普旭63/上海众德63(选配)BUSCH(German)/ ZD(Shanghai)(optional) | |

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | |

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | |

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | |

| 包装速度Packing Speed | 55 - 70包/分钟(根据产品特性和袋型而定)55 - 70 bag/min(depending on ingredients) | |

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | |

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 180mmW:55 - 130mm L:60 - 180mm | |

| 主机功率Host Power | ≈9KW ≈9KW | |

| 耗气量Air Consumption | ≥0.6m³/分钟 | ≥0.6m³/min |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | |

| 外形尺寸Dimension | 2510 x 1600 x 1600mm(L x W x H)(不含提升机)2510 x 1600 x 1600mm(L x W x H)(without elevator) | |

| 主机重量Weight | 2.2T | 2.2 Tons |

| 冷却用水Cooling Water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | |

| 机器型号Machine Model | YD810-1321 | |

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥拉直 ⑦转至真空腔 ⑧盒盖 ⑨抽真空 ⑩封口 ⑪封口冷却 ⑫放气 ⑬出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥bag pulling ⑦passing to vacuum chambers ⑧close the lid ⑨vacuumize ⑩seal ⑪seal&cool ⑫deflate ⑬bag out | |

| 设备材料Equipment Material | 304不锈钢304 stainless steel | |

| 真空泵Vacuum Pump | 德国普旭63/上海众德63(选配)BUSCH(German)/ ZD(Shanghai)(optional) | |

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | |

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | |

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | |

| 包装速度Packing Speed | 55 - 70包/分钟(根据产品特性和袋型而定)55 - 70 bag/min(depending on ingredients) | |

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | |

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 210mmW:55 - 130mm L:60 - 210mm | |

| 主机功率Host Power | ≈9KW ≈9KW | |

| 耗气量Air Consumption | ≥0.6m³/分钟 | ≥0.6m³/min |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | |

| 外形尺寸Dimension | 2510 x 1600 x 1600mm(L x W x H)(不含提升机)2510 x 1600 x 1600mm(L x W x H)(without elevator) | |

| 主机重量Weight | 2.2T | 2.2 Tons |

| 冷却用水Cooling Water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | |

| 机器型号Machine Model | YD810-1324 | |

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥拉直 ⑦转至真空腔 ⑧盒盖 ⑨抽真空 ⑩封口 ⑪封口冷却 ⑫放气 ⑬出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥bag pulling ⑦passing to vacuum chambers ⑧close the lid ⑨vacuumize ⑩seal ⑪seal&cool ⑫deflate ⑬bag out | |

| 设备材料Equipment Material | 304不锈钢304 stainless steel | |

| 真空泵Vacuum Pump | 德国普旭63/上海众德63(选配)BUSCH(German)/ ZD(Shanghai)(optional) | |

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | |

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | |

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | |

| 包装速度Packing Speed | 55 - 70包/分钟(根据产品特性和袋型而定)55 - 70 bag/min(depending on ingredients) | |

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | |

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 240mmW:55 - 130mm L:60 - 240mm | |

| 主机功率Host Power | ≈9KW ≈9KW | |

| 耗气量Air Consumption | ≥0.6m³/分钟 | ≥0.6m³/min |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | |

| 外形尺寸Dimension | 2510 x 1600 x 1600mm(L x W x H)(不含提升机)2510 x 1600 x 1600mm(L x W x H)(without elevator) | |

| 主机重量Weight | 2.2T | 2.2 Tons |

| 冷却用水Cooling Water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | |

| 机器型号Machine Model | YD1012-1318 | ||

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥下料 ⑦拉直 ⑧转至真空腔 ⑨盒盖 ⑩抽真空 ⑪封口 ⑫封口冷却 ⑬放气 ⑭出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥material feeding ⑦bag pulling ⑧passing to vacuum chambers ⑨close the lid ⑩vacuumize ⑪seal ⑫seal&cool ⑬deflate ⑭bag out | ||

| 设备材料Equipment Material | 304不锈钢304 stainless steel | ||

| 真空泵Vacuum Pump | 德国普旭100/上海众德100(选配)BUSCH(German)/ ZD(Shanghai)(optional) | ||

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | ||

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | ||

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | ||

| 包装速度Packing Speed | 70 - 90包/分钟(根据产品特性和袋型而定)70 - 90 bag/min(depending on ingredients) | ||

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | ||

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 180mmW:55 - 130mm L:60 - 180mm | ||

| 主机功率Host Power | ≈9KW | ≈9KW | |

| 耗气量Air Consumption | ≥0.8m³/分钟 | ≥0.8m³/min | |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | ||

| 外形尺寸Dimension | 2550 x 1600 x 1600mm(L x W x H)(不含提升机)2550 x 1600 x 1600mm(L x W x H)(without elevator) | ||

| 主机重量Weight | 2.5T | 2.5 Tons | |

| 冷却用水Cooling Water | 15-20℃, 3.5升/分钟 | 15-20℃, 3 liters/min | |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | ||

| 机器型号Machine Model | YD810-1318 | |

| 工作流程Work Process | ①上袋 ②打码(选配) ③开袋、撑袋 ④下料 ⑤下料 ⑥拉直 ⑦转至真空腔 ⑧盒盖 ⑨抽真空 ⑩封口 ⑪封口冷却 ⑫放气 ⑬出袋①bag feeding ②code printing(optional)③open the bag ④material feeding ⑤material feeding ⑥bag pulling ⑦passing to vacuum chambers ⑧close the lid ⑨vacuumize ⑩seal ⑪seal&cool ⑫deflate ⑬bag out | |

| 设备材料Equipment Material | 304不锈钢304 stainless steel | |

| 真空泵Vacuum Pump | 德国普旭63/上海众德63(选配)BUSCH(German)/ ZD(Shanghai)(optional) | |

| 气动元件Pneumatic Components | 日本SMC/费斯托(标准件)可选配、台湾亚德客(非标件)SMC(Japan)/ FESTO(German)(optional)、Airtac(Taiwan)(non-standard parts) | |

| 驱动方式Driving Mode | 机械传动(凸轮齿轮杠杠全机械模式)Mechanical drive(cam gear lever full mechanical mode) | |

| 封口方式Heat Sealing | 瞬间加热封口、封口完成后瞬间冷却,以确保封口美观Instant heat sealing and instant cooling, ensure nice sealing appearance | |

| 包装速度Packing Speed | 55 - 70包/分钟(根据产品特性和袋型而定)55 - 70 bag/min(depending on ingredients) | |

| 包装袋材料Pouch Type | 三边封袋、铝箔袋、尼龙袋、纸袋等覆膜袋3-side sealing bag, Aluminum foil bag, Nylon bag, Compound bag, paper bag, etc | |

| 包装袋规格Pouch Dimension | 宽:55 - 130mm 长:60 - 180mmW:55 - 130mm L:60 - 180mm | |

| 主机功率Host Power | ≈9KW ≈9KW | |

| 耗气量Air Consumption | ≥0.6m³/分钟 | ≥0.6m³/min |

| 驱动电源Drive Power | 三相五线 380V 50HZ3-phase 5-wire system 380V 50HZ | |

| 外形尺寸Dimension | 2510 x 1600 x 1600mm(L x W x H)(不含提升机)2510 x 1600 x 1600mm(L x W x H)(without elevator) | |

| 主机重量Weight | 2.2T | 2.2 Tons |

| 冷却用水Cooling Water | 15-20℃, 3升/分钟 | 15-20℃, 3 liters/min |

| 使用环境Use Of The Environment | 室温10-40℃,30-90%RH,无结露,无腐蚀性气体,无灰尘等其他恶劣坏境Room temperature 10-40℃, 30-90% RH, No Condensation, No Corrosive gas, No dust and other harsh environment. | |

本文由网络转载,仅供给袋式包装机爱好者研究学习,若涉及侵权,请联系客服删除。

|

上一条:给袋机凸轮机构设计的一般步骤 |